A throttle position sensor (TPS) is a necessary component in modern vehicles that sends information about the amount of gas that goes into the engine.

When a TPS fails, it can cause various symptoms since the air-fuel ratio will be incorrect, which can cause the engine to run badly.

What is the Throttle Position Sensor?

The throttle position sensor reports the angle opening of the throttle body plate.

A throttle body plate opens as the gas pedal is pressed to allow more gas to enter the engine.

The computer (ECM) uses this information to adjust the air-fuel ratio going into the cylinders.

When the TPS fails, the computer (ECM) does not know how much fuel should be going into the engine.

How Does the Throttle Position Sensor (TPS) Work?

The TPS is attached to the throttle body plate, which opens and closes as the gas pedal is pressed.

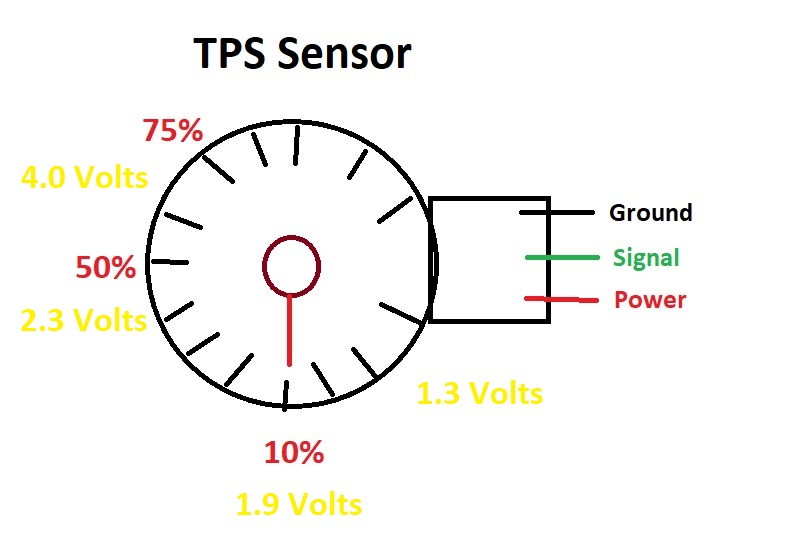

A TPS is a potentiometer that changes resistance as it turns.

The vehicle computer reads the resistance changes to know the location of the sensor.

As the TPS turns, it touches contact points, which causes the output voltage to change.

For example, an engine at idle may have the TPS sensor at 1.3 volts, but when the throttle is half open, it may read 2.3 volts.

When a TPS starts to fail, the contact points are no longer allowing voltage to pass through or has thrown the voltage off.

Contact points at certain sections have become worn or broken.

Some sections are often still working, but when the sensor reaches a bad contact point, there is a bad signal.

A bad contact point can cause voltage spikes or jumps or just be a dead spot.

When the signal is bad, the computer (ECM) has bad data and can not correctly adjust the air-fuel ratio going into the engine.

For example, all the contact points in a TPS may be good except at the 15 percent mark.

When the throttle is open to the 15 percent mark, there is no voltage and the engine runs badly.

The engine may run well otherwise, but anytime it reaches the bad contact the furl gas ratio is thrown off, which causes an issue.

Symptoms of a Bad Throttle Position Sensor

- Engine Light On

- Rough Idle

- Surge in Idle

- Worse MPG

- Limp Mode

- Engine Stalling

- Trouble Accelerating

The engine light will likely come on since the air-fuel ratio is off.

When the engine light comes on, an OBDII scan tool can be used to read any error codes that will point to the issue.

For example, a “P0121 TPS “A” Circuit Range Performance Problem” is an OBDII code that is often given when a TPS sensor goes bad.

A bad TPS sensor can cause the engine to idle roughly or badly.

This is caused by the air-fuel ratio being off since the onboard computer is receiving bad data for the location of the throttle body plate.

A surge in idle is often reported when there is a bad TPS sensor.

There can be unpredictable results when the senor goes bad since the voltages are thorn off.

Often, fuel economy is worse with less MPG than usual.

The EMC may be dumping more fuel than needed at certain times, causing the miles per gallon to be worse.

When the ECM detects the sensor to be very off, it may send the vehicle into Limp Mode.

Limp Mode can vary depending on manufacture, but the speed and power of the car or truck will be greatly reduced.

The engine may stall out when driving or stepping on the gas pedal.

This is caused by a bad contact point in the TPS sensor that has worn out or gone bad.

If many contact points have failed in the sensor, there can be problems when accelerating.

The sensor will need to be replaced for the acceleration to be normal again

How to Test a Throttle Position Sensor

- Use an OBDII scan tool to scan for error codes.

- Use a Multi Meter to test the sensor.

A multi meter can be used to test the throttle position sensor.

Since the TPS is a potentiometer, the same testing methods apply as they would to a variable resistor.

The resistant values are read using ohms on a multi meter.

The TPS sensor is turned, and the values should steadily increase with no jumps or drops.

If there is a jump or drop in resistance as it is turned, that is a bad contact point, and the sensor will need to be replaced.